What are the costs of poor pallet stability?

Pallet stability is a problem across the FMCG industry. In this blog we will discuss the costs of poor pallet stability.

Product Damage

The Packaging Digest estimates that as much as 11% of all unit loads arriving at a distribution centre have some level of case damage.

One of the biggest causes of product damage during transit is poor pallet stability. Unstable pallet loads will move during transit which can result in loads collapsing and becoming damaged. This leads directly to financial losses as damaged goods need to be replaced or repaired.

Product damage can be particularly problematic for companies transporting liquids. Not only are liquids inherently unstable, but movement can cause primary packaging (bottles etc.) to crack or break causing leaks. The product then spills throughout the whole load and damages goods that would otherwise still be sellable.

As an extreme example, we witnessed a beverage manufacturer who was experiencing such a severe problem with pallet stability that they were emptying entire loads into a skip and writing the goods off as waste.

Increased Waste & Sustainability Impact

Discarding damaged or unstable pallets can negatively impact a company’s sustainability efforts. Every product produced has a carbon footprint and by preventing unnecessary product wastage, you can decrease your overall environmental impact. In addition, repacking and reshipping unstable loads is using additional plastic and causing additional carbon emissions which could have been avoided.

Spillages caused by shifted loads can cause environmental damage, especially if you are transporting hazardous goods such as chemicals. In these situations, there is often a significant clean-up cost incurred.

Efficiency Losses

Unstable pallets are difficult to safely move and handle, reducing warehouse efficiency. Many automated warehouses refuse to accept unstable pallets due the difficulties they cause within their automated storage systems.

Safely unloading unstable pallets or distressed loads is very time consuming which can cause operational delays and slow down your supply chain. One global brewer explained that, because of the time required and inconvenience of unloading distressed loads, any affected trailers were often left parked for weeks before being delt with. This caused financial damage as every trailer which remained parked on site for an extended period of time was not delivering goods to their customers and generating revenue.

On the other hand, improving pallet stability may enable efficiencies that were previously unobtainable such as space saving gains by stacking pallet during storage and transport.

Reworking, Repacking & Reshipping

We have already discussed how repacking and reshipping damaged loads has a negative environmental impact but there is also a monetary cost.

Reworking distressed loads is a very manual and laborious task. Taking operatives out of your warehouse to deal with shifted or problematic loads is not an effective use of labour hours or time.

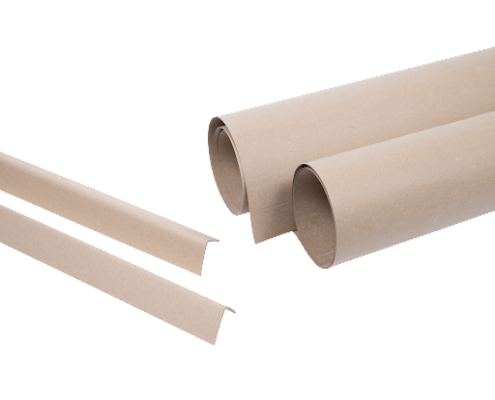

Repacking loads incurs the cost of additional packaging materials (pallet wrap etc.) which could have been prevented by solving pallet stability problems.

The transport costs of reshipping the repackaged pallets or replacement goods is another unnecessary cost.

Distributor/Retailer Fines & Charges

It is not uncommon in the industry for distribution centres or retailers to charge the manufacturer for unstable pallets. This is usually in one of two ways:

- Fines for the inconvenience of distressed loads.

- Reworking and repacking charges for the time and cost of dealing with damage pallets.

Health & Safety Risks

EUMOS estimates that one person is killed or injured every hour in the UK and Europe due to insecure cargo.

There is no cost that can be put on human life or bodily harm and the resulting lawsuits can be very damage financially and to brand reputation.

Higher Insurance Premiums

A history of accidents or claims as a result of poor pallet stability can result in higher insurance premiums for liability and property coverage.

Damage To Brand Reputation

Damage to brand reputation is an intangible cost which is often overlooked. Logistics providers and retailers do not like working with brand who have a reputation for delivering problematic loads. This can damage brand reputation and customer relationships.