Understanding Hand Pallet Wrap Core Types

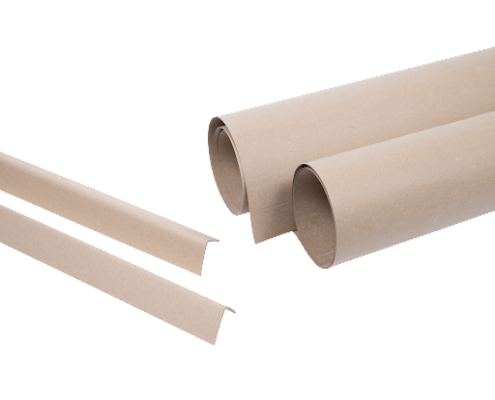

Hand pallet wrap is widely used across many industries to secure goods for transit and storage. One key aspect to consider when selecting hand pallet wrap is the core type. Hand pallet wrap is commonly available in two different core variations: flush core and extended core. In this blog we will discuss the simple differences between the two.

Flush Core

Flush core hand pallet wrap refers to the type where the core, or cardboard tube, extends only to the width of the film. Flush core pallet wrap is applied by inserting your fingers inside the core and letting it spin on your fingers as you wrap the pallet. This can often cause painful friction burns for the operator, so it is a good idea to wear gloves. Flush core pallet wrap can also be applied using a hand dispenser. This allows for faster and safer application. As flush core hand pallet wrap is smaller that extended core hand pallet wrap, it makes it a suitable choice for industries where space saving is critical.

Extended Core

Extended core hand pallet wrap features an elongated handle that extends beyond the width of the film itself. This creates a built-in handle which provides a convenient gripping point for application. The operator is able to hold the core and let it spin in their hand as they wrap the pallet. Extended core pallet wrap can also cause friction burns on the palms of your hands over time, so it is a good idea to wear gloves.

Coreless Pallet Wrap

A recent innovation is coreless pallet wrap. This is where there is no cardboard tube in the centre of the film and instead the film is left hollow in the middle. Removing the cardboard core helps to reduce cost and waste. However, without a core the film cannot be wound tightly meaning the roll size is larger and more cumbersome and the roll lengths are considerably shorter.

Conclusion

The difference between flush and extended core hand pallet wrap is very simple. The length of the core and the way in which they are applied. However, which one should you use?

There is no right or wrong answer as the core makes no impact to the performance of the film. The core choice is often determined by the operator preference, which one they find easier and most comfortable to use. It is therefore best to consult the operators before making a decision to find out their preferred type.

If you are unsure about which hand pallet wrap core type would be most suitable for you or your operators, then you can request a sample of each to trial.